Navigating the complexities of the sock supply chain can be a daunting task. Whether you’re a seasoned retailer or a new player in the market, building and maintaining a fruitful relationship with your sock suppliers is key to your business’s success. So, how can you ensure that this partnership is not just sustained but also thrives?

From communication strategies to understanding the nuances of the sock industry, let’s uncover the five critical tips for fostering successful cooperation with your sock suppliers.

1. Establish Clear Communication: The Foundation of Success

Effective communication is the cornerstone of any good supplier relationship. Misunderstandings can lead to errors in orders, delays, and ultimately, a strained relationship.

- Actionable Tip: Be clear and concise in your requests and feedback. Regularly scheduled calls or emails can keep both parties aligned.

- Key Benefit: Consistent and transparent communication minimizes errors and builds trust.

2. Understand Their Processes: Knowledge is Power

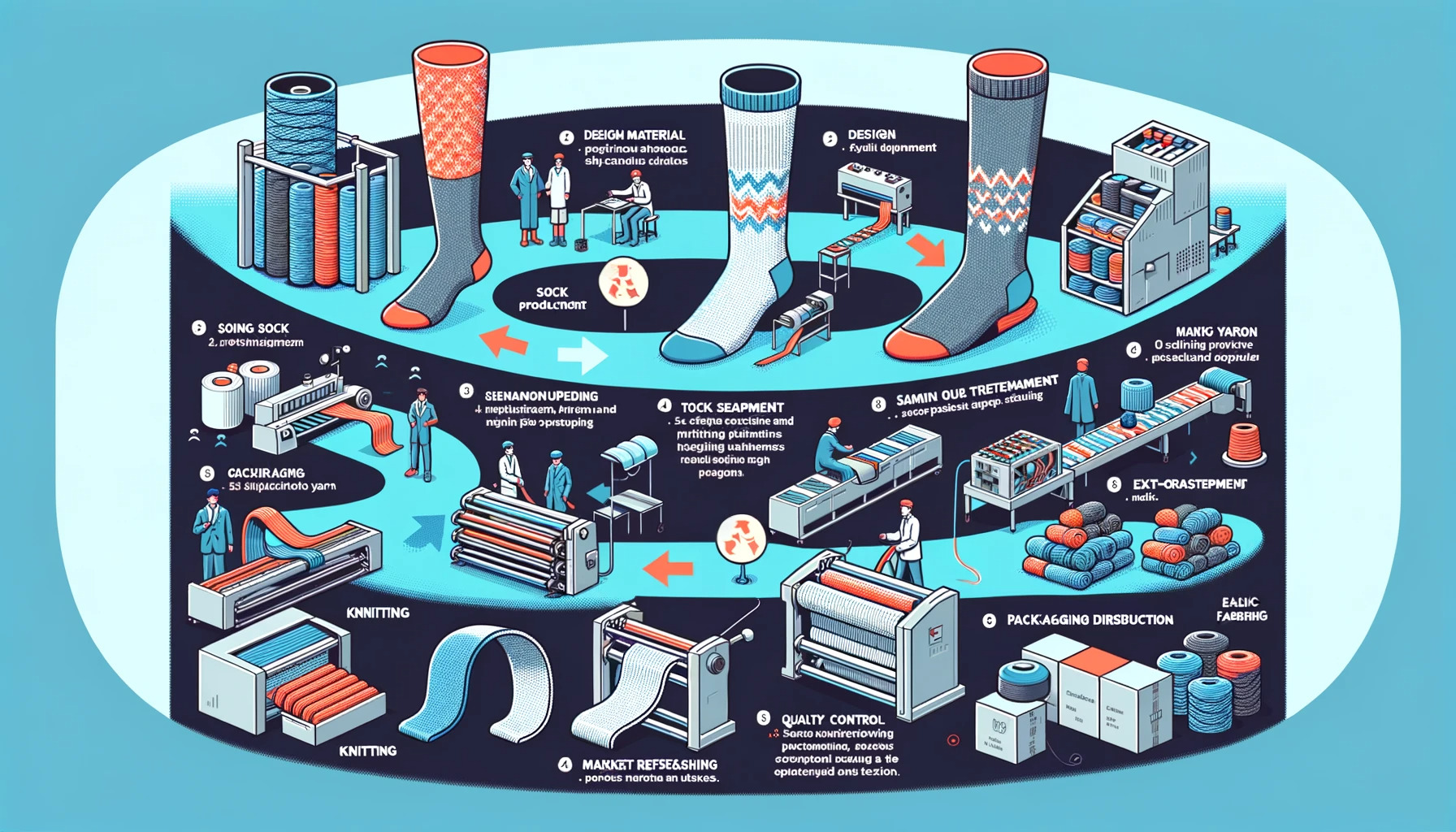

Each supplier might have different methods of production, quality control, and logistics. Understanding these can help you tailor your requests and expectations accordingly.

- Actionable Tip: Take time to learn about their manufacturing processes, quality control measures, and shipping procedures.

- Key Benefit: This knowledge helps in setting realistic expectations and can aid in smoother collaboration.

3. Build a Partnership, Not Just a Transaction

Viewing your supplier as a partner rather than just a vendor can lead to better cooperation and mutual growth.

- Actionable Tip: Show interest in their business challenges and objectives. Where possible, offer support or advice.

- Key Benefit: A partnership approach often results in better service, loyalty, and priority treatment.

4. Be Proactive with Feedback: Encourage Continuous Improvement

Regular, constructive feedback is vital. It helps suppliers understand your needs better and gives them the opportunity to improve.

- Actionable Tip: Provide both positive feedback and constructive criticism. Be specific about what you liked and what needs improvement.

- Key Benefit: Constructive feedback leads to continuous improvement in product quality and service.

5. Plan for Contingencies: Expect the Unexpected

In any supply chain, unforeseen circumstances can arise. Having contingency plans in place can save you from major disruptions.

- Actionable Tip: Develop a backup plan for critical aspects like material shortages or shipping delays.

- Key Benefit: Preparedness for contingencies ensures business continuity and reduces stress and losses during crises.

Conclusion

Successful cooperation with sock suppliers hinges on clear communication, understanding their processes, building a partnership, providing feedback, and planning for contingencies. By embracing these tips, businesses can forge stronger, more resilient relationships with their suppliers, paving the way for long-term success and stability.